Electronics Production

During the summer of 2019, I decided to purchase my very 1st CNC machine to use in my home. My hopes were to start a new hobby in fabricating electronic devices, so I can learn more about its design workflow and to spark new ideas for my Fab Lab courses.

CNC 1610 PRO

https://www.amazon.com/dp/B07K83MS4Z/ref=nav_timeline_asin?_encoding=UTF8&psc=1

I started by doing some extensive research on the CNC milling machine that I thought was compact, cheap, and could use file types I could generate with software that I’m familiar with. What I found on Amazon.com was the CNC 1610 Pro which had a 160mm x 100mm bed area, and was used to primarily carve into woods, plastics, and copper circuit boards. The price for this machine was around $165. I predicted that this machine would prove to be very rigid/compact for my uses which only involved cutting copper circuit boards that are up to 4in x 6in (101.6mm x 152.4mm).

Custom Laser-cut Bedding

The best method I’ve learn to mount a blank copper board is by using double-sided tape. The aluminum rail design provided with the CNC was not smooth or flat enough to allow this feature. I decided to then design a cast acrylic bed, that can be bolted on to provide a flat surface for the tape to stick onto. This design would also prove useful by showing laser engraved marks which I could line up blank circuit boards to for mass production.

Using Fab Modules

www.fabmodules.org

One of the most important features I’ve learned during my Fab Academy schooling in 2017 was using their open-source, web-based application called Fab Modules. By simply importing a black and white image that I designed from KiCad, Fab Modules generates a tool path with the ability to tweak any desired setting before outputting a variety of different G-code file types, used for most typical CNC machines.

Fab Modules provide a set of software tools for personal fabrication, intended for use with machines common to fab labs.

It includes

Tools to design 2D and 3D objects

Functions to generate 2D and 3D toolpaths

GUIs workflow from design files to machine commands

**For my CNC 1610 Pro, I only used Fab Modules as a software to generate the .NC (G-code) file from a .PNG image. Once Fab Modules provided that G-code file, I was ready to use another application that came with the CNC 1610 Pro, called “Candle.”

Using Candle (GRBL Software)

Because the CNC 1610 Pro is operated by a circuit board that runs off GRBL control, I was unable to properly connect Fab Modules to the CNC 1610 Pro to run the G-code file that I generated from Fab Modules. For anyone that doesn’t know, GRBL is a firmware for Arduino boards or similar that controls stepper motors and spindles.

I decided to go an easier route by using the provided CNC application called Candle

Candle is a CNC controller application with G-Code visualizer.

Supported functions:

Controlling GRBL-based cnc-machines via console commands, buttons on form, numpad

Monitoring machine state

Loading, editing, saving and sending of G-code files to machine

Visualizing G-code files

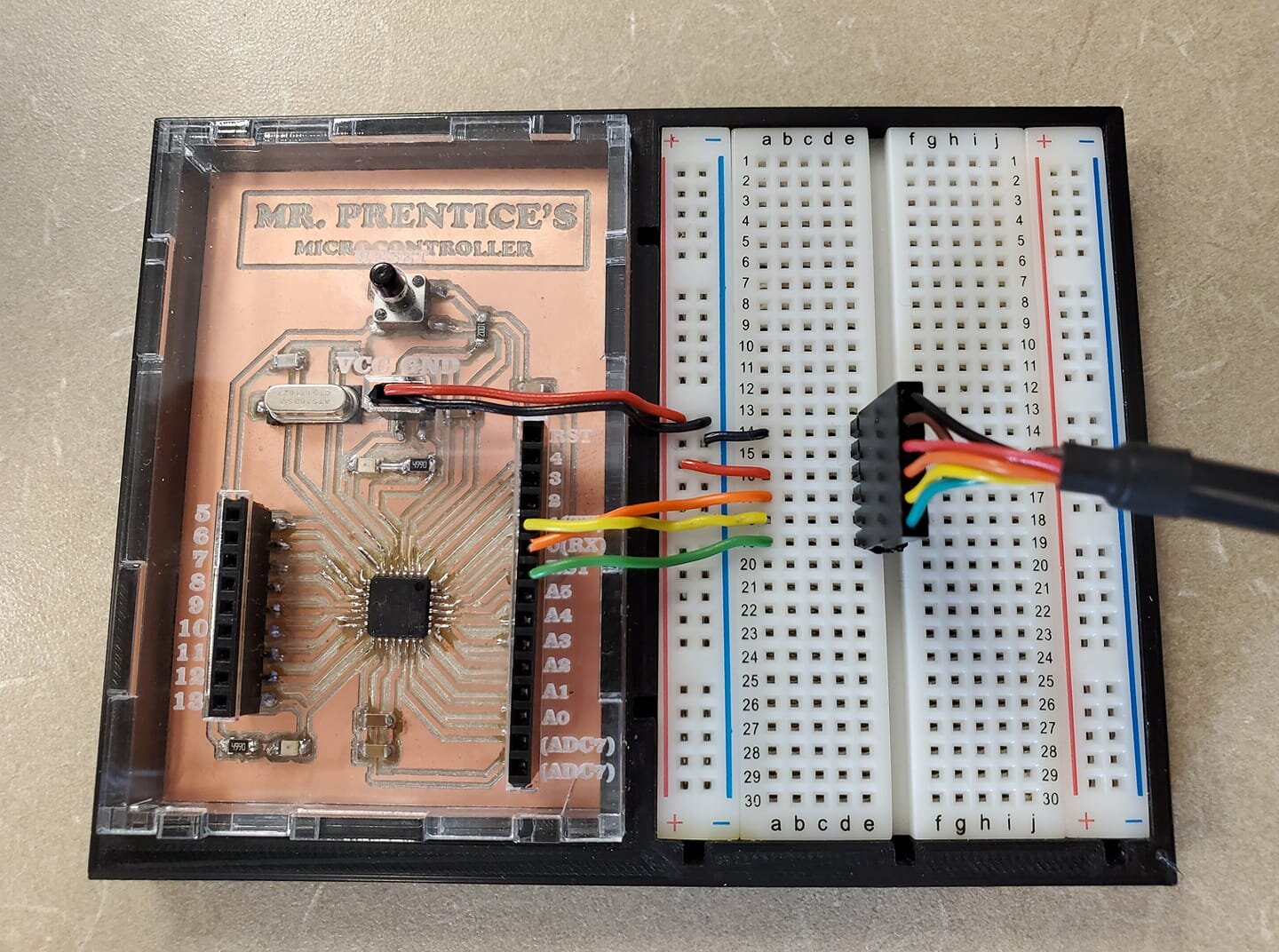

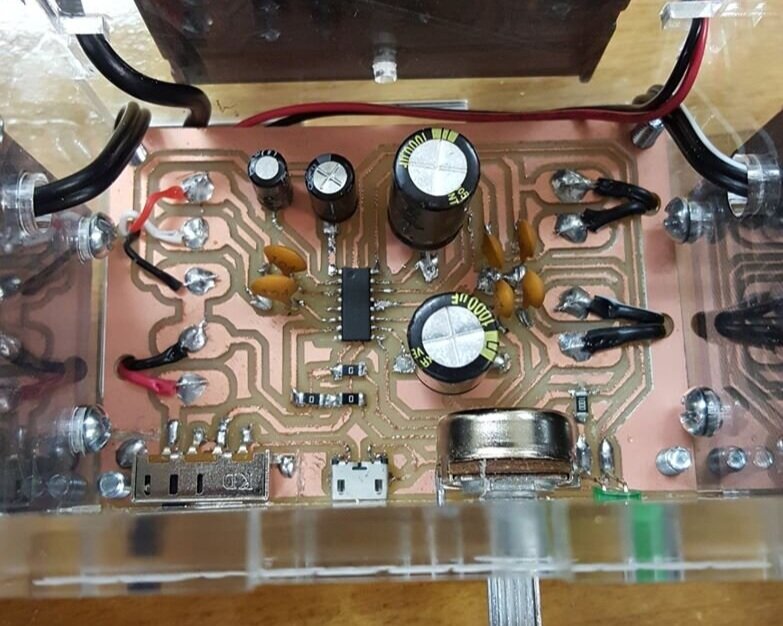

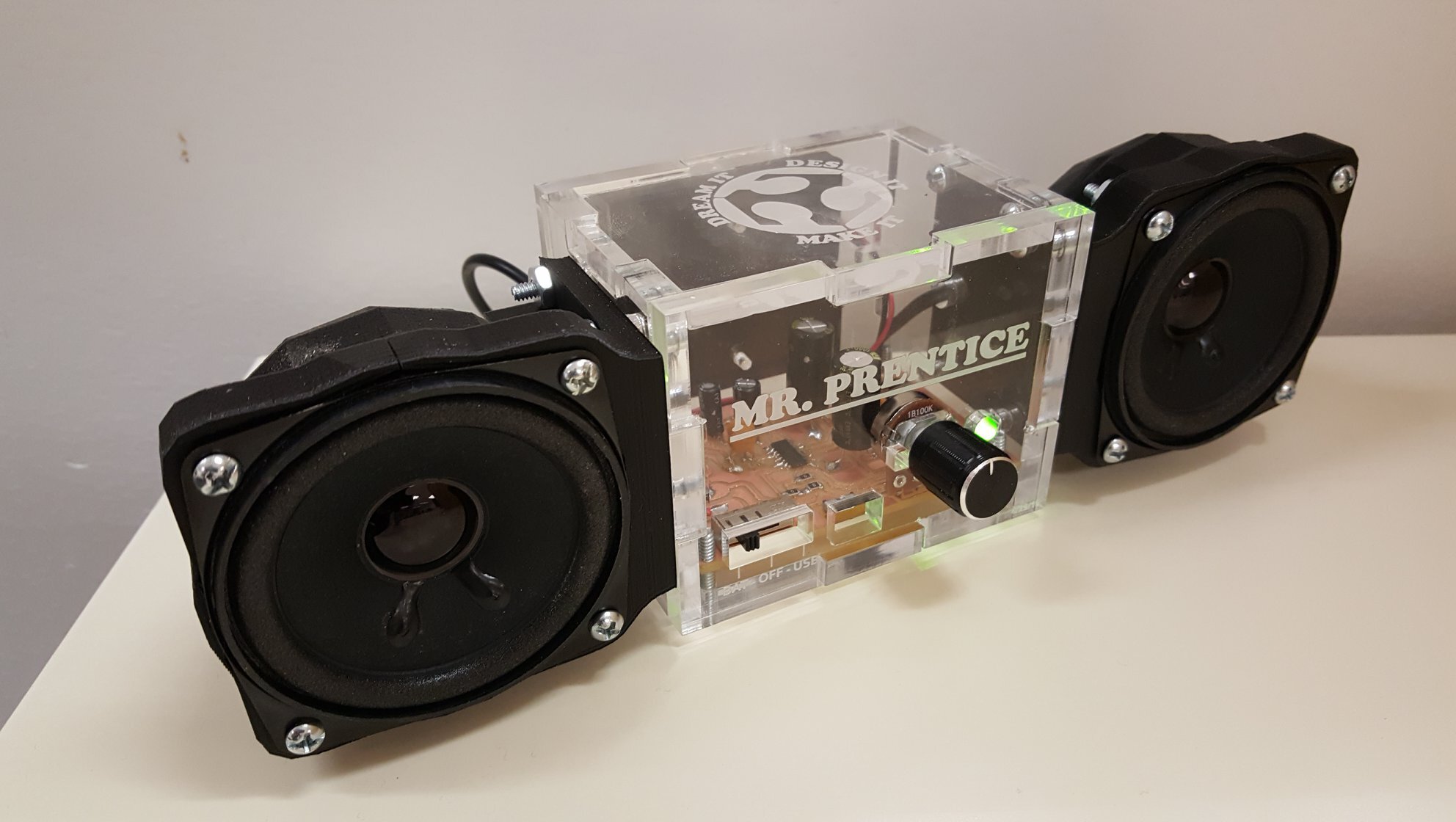

Finished Electronic Projects

What went wrong?

CNC 1610 PRO BREAKS AFTER 5 MONTHS USE

Sometime around November of 2019, the Y-Axis stopped working in the middle of a cutting operation. After doing some troubleshooting on all of the components, I found out that it was just the Y-Axis control board on the circuit that must have over-heated. It was a small break-out board that I could unplug from the main circuit to hopefully replace. The issue was that I could not get any feedback from the Amazon vendor that I purchased it from, and couldn’t find any spare parts on the market.

While this was happening, my employer at Trinity high school just purchased the more industrial desktop milling machine (Roland SRM-20) that had a much better quality in it’s production and design. I stored my broken 1610 Pro away for the next few months to give me time to learn the Roland SRM-20.

It is April 2020, and I now decided that I wanted to continue having the option of fabricating circuit boards from my own home instead of work. I was not willing to spend $5,000 for my next CNC machine, so I decided to buy the exact 1610 Pro model I purchased last summer. All that I needed was the control board, but buying a 2nd one would provide me more spare parts for a cheaper price.

Came with New Control Board Design & Cooling Fan

Complete surprise to me since it wasn’t shown in the advertisement

I saw this as a win for me overall though because instead of spending $5,000 on the machine I would want, I’ve only invested $400 on a machine that simply gets the job done, along with having it’s spare parts ready.